Behind the scenes: How lanyards are made

We have seen our lanyards worn by remarkable people doing remarkable things in social and environmental justice. Lanyards increase your brand’s visibility and help you keep your name and credentials visible throughout your event. In some cases, folks may reuse their lanyards as key chains, but in others, they are tossed into a drawer or trashed.

In this article, we’re going to share some design considerations, behind the scenes about how lanyards are made and how you can reduce lanyard waste for your next event.

What are lanyards for?

Lanyards serve many purposes, but they are most often used at events and conferences as name badges or to display your conference credentials. Organizations sometimes use them for staff and visitors to hold security passes or keys in the office. In the context of events and conferences, they’re actually great visibility for sponsors. While we love our lanyard lending library, we know some events want to offer the lanyards as an opportunity for sponsors – knowing the sponsor logo will be in all photos or media shots.

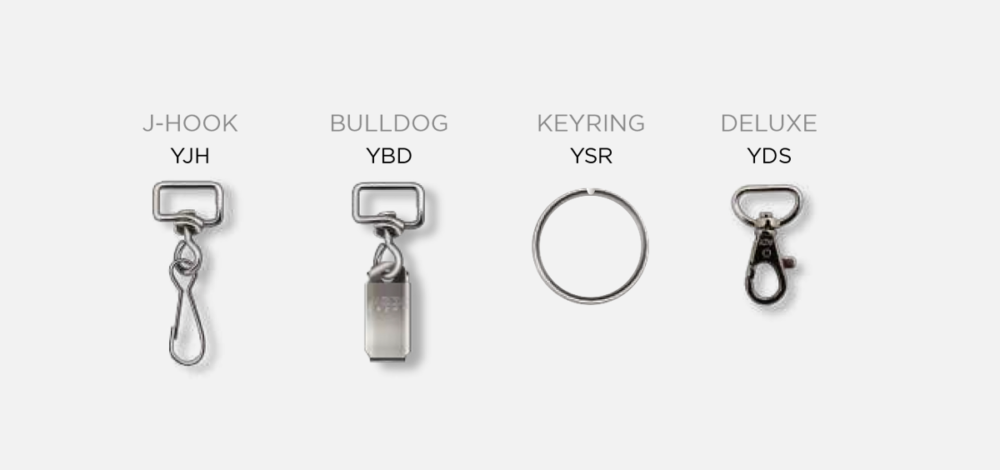

Lanyards are usually woven fabric and imprinted with a logo or branding. They have a small metal ring or clip at the bottom to hold your credentials. Various clips are available, including:

- Bulldog clip

- Split key ring

- Swivel J-hook

- Swivel bulldog clip

- Split key ring with bulldog extender

- J-hook w/ split key ring

- Lobster clip

You’ll have many options to create and customize your lanyard. Some of these options include:

- Full-colour printing vs. logo-imprinting

- Variety of fabric, weaves, material choices, and thicknesses

- Included safety breakaway

- Reflective strips for increased visibility

How lanyards are made: The lanyard-making processes

Here’s a behind-the-scenes look at three popular lanyard production and printing methods.

Woven

A twilling machine can make blank, woven lanyards that can be screen printed or can even weave the logo into the lanyard.. To weave the design directly into the lanyard, designs are uploaded to a special weaving machine, which produces about 1,200 units per 10-hour shift (compared to 3,000 in a 10-hour shift for blank lanyards). The result is a high-quality, long-lasting lanyard with your logo literally embedded in the product.

Silk screening

Silk-screening your lanyard uses a stencil and special ink to add designs to your lanyards.

Here’s the process to screen print designs on blank lanyards:

- Lay ribbons: The ribbons are laid flat in rows on a long table (up to half the length of a football field in some facilities).

- Apply a clear coat: A clear coat in the finished design is stencilled on the lanyards so the screen printing ink adheres better.

- Stencil the design: Use a screenprinting form with the stencilled design to apply several thin layers of ink.

Sublimation

Using sublimation to imprint your design on a lanyard is more efficient (and faster) than silk screening. Your design is printed on special sublimation printers, which use a special sublimation ink (which will adhere to the lanyard fabric when applied and heated). This allows for full-colour printing and vibrant logo treatments.

Here’s the process to sublimate images lanyards:

- Print the designs: Printing is done on a long, continuous roll of specially formulated sublimation paper. For a 5000-piece order of lanyards, you’ll need about 360 yards of paper when printing 14 at a time. That will double if you’re printing on 2 sides of the lanyard.

- Prepare and preshrink lanyard ribbons: The lanyard fabric or ribbon is fed through a large machine and heated to 500oF to preshrink the material and to make the ribbon smooth and shiny.

- Apply sublimation prints: The printed strips (from step 1) are fed on top of the lanyard ribbon and fed through a drum together. This drum applies heat and pressure so the design transfers off the sublimation paper and onto your ribbon. This process is repeated if you’re printing double-sided.

- Cut the lanyards: Until this point, the ribbons are one long strip. They are now put on a cutting table where the lanyards are cut to the desired length, and the heated blade gently melts and seals the cut edges to avoid fraying.

- Sew attachments: Next, the metal attachments are sewn on each lanyard, boxed, and prepared for shipping to the customer.

Reducing lanyard waste with the Lanyard Lending Library

At Fairware, we love making custom lanyards for our customers, but we recognize the waste this often produces after your event is over. That’s why we created the Lanyard Library. We lend you generic lanyards for your event that are ethically made from recycled plastic polyester.

When you’re done with your lanyards, collect them from your attendees and return them to us to receive your deposit back. They’re free to borrow and we provide collection boxes and FAQ on how to maximize the returns.

You only pay for shipping and provide a refundable deposit per lanyard. You receive your deposit back when you return your lanyards (as long as you send back at least 85% of your order). If less than 85% are returned, you’ll be charged $2.50 per lanyard.

This is just another way we’re trying to reduce tradeshow and conference waste. Read our Lanyard Library FAQ or order your lanyards today.